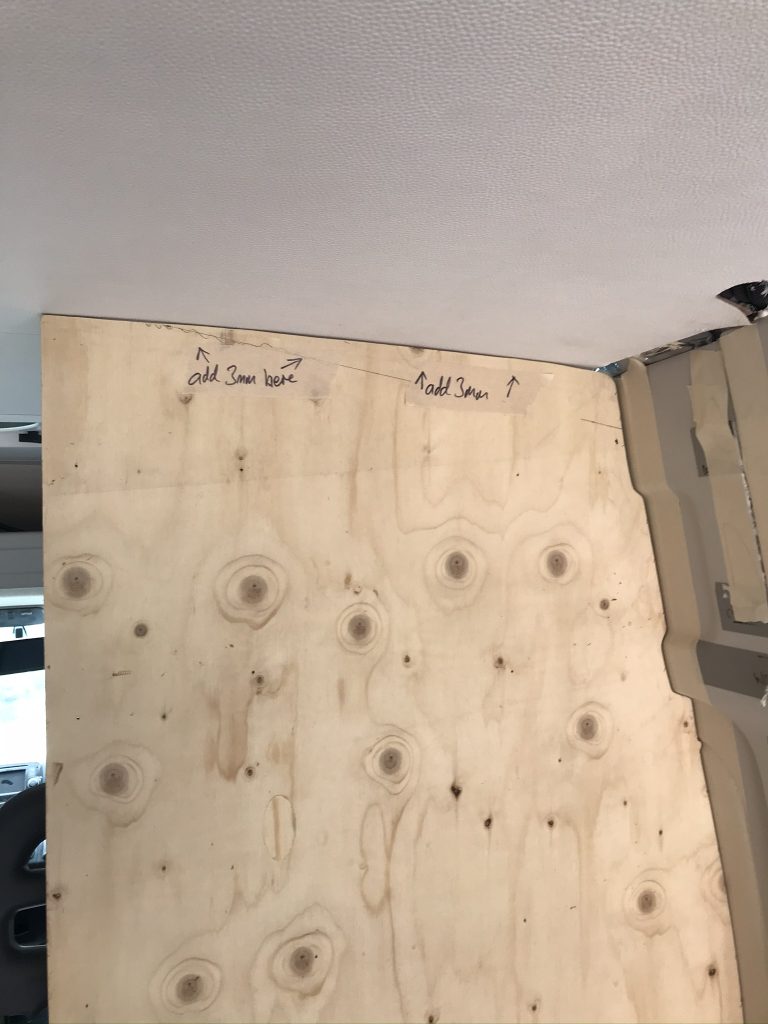

This Peugeot Boxer camper-van used 10 sheets of 15mm Lightweight Ply its hard to see where it all went but I was left with hardly any waste. Lightweight Ply isn’t cheap, at £150 a sheet (many cost more) then you dont want to be making too many errors. To avoid unnecessary errors and wastage I recommend making templates. In fact I made a template for every piece of furniture in this vehicle. It took a lot of extra time but it was worth the time spent. A template will allow you to check the fit and also let you see what the finished result is like. On occasion I made changes and was so glad I didn’t use the 15mm ply without checking first.

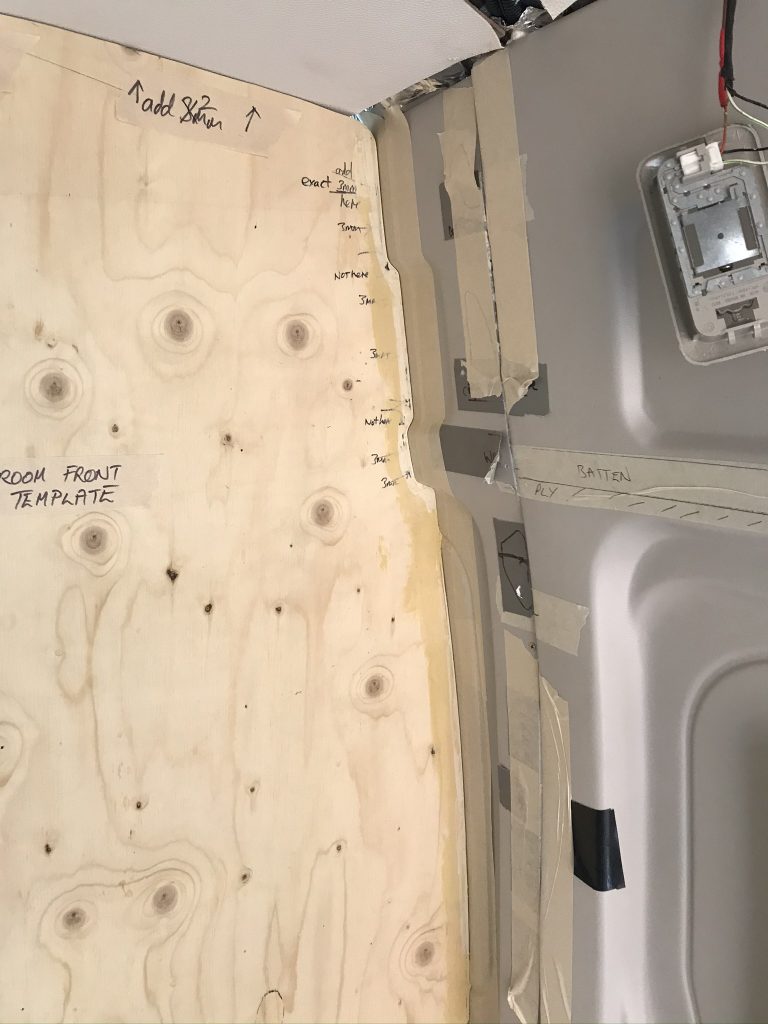

Below: I am making the side of the wet-room wall out of some used boards that were scrap (or for use elsewhere). I started by making a cardboard profile then cutting the wood. The shape is not easy to get right as the plastic panels are a complicated shape. Often van builders wont try to follow the exact profile, there is a rubber edging product that sits between the wall and side of the van. I didn’t want to do this, instead I wanted my panels to form the exact profile. Below I will show you a way to do this.

Below: look carefully at the edge of the wood notice the yellow areas? I’ll explain what this is in a moment. The problem with plastic panels is that they may not be rock solid with fitted. This means when you press against them they can bend. I needed a way to prevent gaps appearing between the plastic panels and the wall panels I am making. I explain this in better detail in another post but for now I will explain what the yellow patches are. Firstly I cut the wood panel as close as I could, however, as much as I tried it wasn’t totally perfect. To get it perfect I stuck a layer of masking tape onto the wall and applied grease to the tape. Next I placed my wood panel against the plastic wall panel and filled any imperfections with wood filler. In short I made an exact profile of the plastic panel onto my wood panel. I now had an accurate template I could work from.

Below: I almost made the entire wet-room as a mock-up. This was a good idea as it allowed me to position it and make sure my drainage holes were located in the right position and not over a cross-member in the chassis. It also gave me an idea of what it would look like and how much space I have available.

Below: You cannot use a spirit level in a van. I made my own 90 degree straight edge to make sure the panels aligned correctly.